March 25, 2022

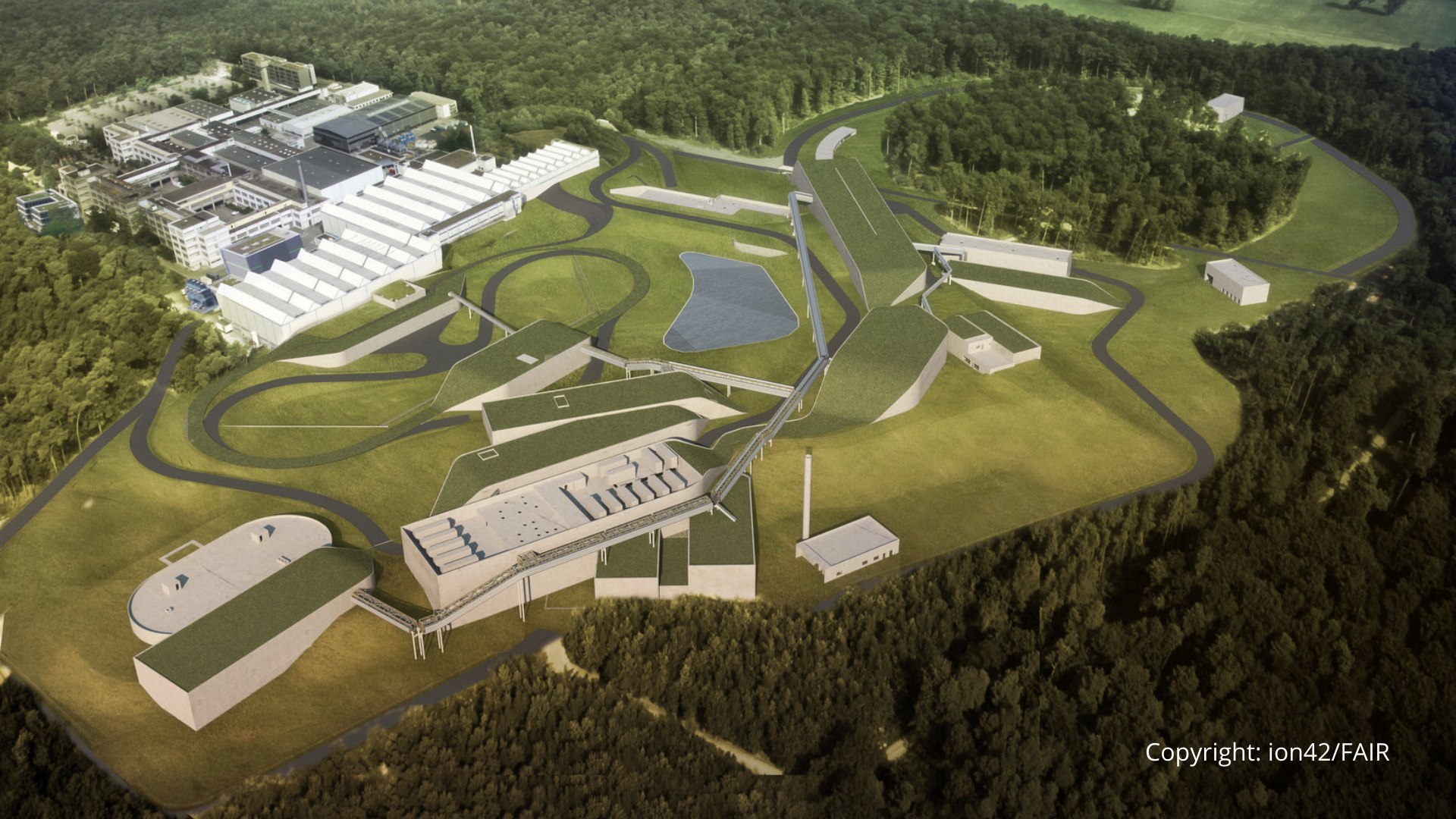

Selected by GSI for the design, development, engineering, manufacture, installation, and commissioning of power converters for the main dipole and quadrupole magnets of the ring accelerator SIS100 at the new Facility for Antiproton Ion Research (FAIR), an accelerator facility in Darmstadt, Germany, GE Power Conversion Germany is supporting one of the largest scientific research projects in the world.

Challenge

At FAIR, matter that usually only exists in the depths of space will be reproduced in a lab for research. Scientists will be able to gain new insights into the structure of matter and the evolution of the universe from the Big Bang to the present.

The latest technologies, including innovative measurement methods and techniques, information technology and superconductivity technology, are being developed for the FAIR particle accelerator. For this purpose, experts at FAIR and GSI are working closely together with teams all over the world.

Accuracy and control of the systems must be assured and maintained along the way, as they pose main challenges of ensuring reliable technology. Highly customized and flexible power technology are the foundation of a scientific research project of this scale.

Solution

GE Power Conversion’s state-of-the-art power technology with its low-voltage IGBT inverters from the LV8 power electronics platform (LV8 platform) will help to address research, development, and technical challenges in the most flexible way.

The classic approach for ring accelerator supplies is based on Thyristor technology in combination with a large number of small MOSFET stages to flatten the output current as required by this kind of application. A major disadvantage of this approach is a high effort for reactive power compensation caused by Thyristor operation and an extremely high number of MOSFET devices to flatten the current ripple caused by Thyristor bridge operation.

For the SIS100 main supply an adapted solution based on LV8 standard building blocks has been offered. An ‘Active Front End’ converter will be used to convert AC power to DC power and vice versa to magnetize or demagnetize the magnets of the main accelerator ring. During current ramp-up or ramp-down, peak power levels of about 20 MVA will be achieved.

An extreme challenge is the accuracy and flatness of DC output current. The rated DC output current is 13.5 kA with an accuracy of 10 ppm – including the DC output ripple. To achieve these extreme hard requirements with PWM mode DC choppers pulse interlacing of paralleled choppers is applied. Target pulse frequency of a single chopper will be 5 kHz. By applying 12-fold pulse interlacing an effective output ripple frequency of 60 kHz will be achieved, which reduces the DC output filter effort significantly.

Besides the accuracy requirements, the control of the system is another challenge: The main power supply has to be integrated into an existing arrangement to interact with about 1000 other power converters – without latency. Because of the superconducting magnets a special dump circuit will be part of the system to prevent the superconducting material from overheating in case of a cooling issue.

It can be customized for either AC drives with rotating machinery or DC loads such as magnetic power supplies, each with single- or multi-quadrant capability. In addition, particularly powerful IGBT switches are provided for quench protection of the superconducting magnets. The power electronics will be implemented with system components such as power transformers, medium-voltage switchgear, surge arresters and fast semiconductor fuses.

Benefits

These new switch-mode power supplies replace earlier generations of Thyristor power supplies with their fast FET (field-effect transistor) ripple compensators. Switching power supplies have enhanced functionality, providing both power current to the magnets (formerly thyristor power converters) and smoothing the ripple of the same (formerly FET arrays).

The total power of the switch-mode converters is about 40 MW for the main dipole magnets and their quadrupole magnets.

GE Power Conversion’s state-of-the-art technology with it’s IGBT inverters from the LV8 platform are highly efficient, highly flexible, and adaptable to the most varied special requirements.