Kelman DGA 900 PLUS

9 gas on-line DGA expandable with add-ons to a Transformer Monitoring System (TMS)

The Kelman DGA 900 PLUS is a member of the next generation of multi gas monitors. Built from the DGA 900 platform, the PLUS extends the monitoring capability beyond just DGA.

Knowledge of the condition of transformers is essential for all electrical networks and on-line monitoring of transformers is an increasingly vital component of successful asset management programs. The comprehensive information provided by the Kelman™ DGA 900 PLUS not only allows expensive failures to be avoided but enables asset capabilities to be maximized.

The Kelman DGA 900 PLUS builds on the standard 9 gas DGA and moisture capabilities of the DGA 900 by enabling the addition of extra sensors, electronic cards and firmware algorithms to expand its monitoring capabilities. Bushing monitoring, partial discharge detection, OLTC monitoring, transformer models are amongst the options available to offer an integrated system which delivers a more in-depth picture of the transformer’s overall condition and will monitor the root causes of most transformer failures.

Kelman DGA 900 PLUS

9 gas on-line DGA expandable with add-ons to a Transformer Monitoring System (TMS)

The Kelman DGA 900 PLUS is a member of the next generation of multi gas monitors. Built from the DGA 900 platform, the PLUS extends the monitoring capability beyond just DGA.

Knowledge of the condition of transformers is essential for all electrical networks and on-line monitoring of transformers is an increasingly vital component of successful asset management programs. The comprehensive information provided by the Kelman™ DGA 900 PLUS not only allows expensive failures to be avoided but enables asset capabilities to be maximized.

The Kelman DGA 900 PLUS builds on the standard 9 gas DGA and moisture capabilities of the DGA 900 by enabling the addition of extra sensors, electronic cards and firmware algorithms to expand its monitoring capabilities. Bushing monitoring, partial discharge detection, OLTC monitoring, transformer models are amongst the options available to offer an integrated system which delivers a more in-depth picture of the transformer’s overall condition and will monitor the root causes of most transformer failures.

Transformer Failure Modes

Transformer Failure Modes

Benefiting from over 15 years of multigas DGA vendor experience and over 15,000 devices in the field, the DGA 900 encapsulates learnings and improvements derived from its predecessors to bring improved performance, innovative new features, enhanced user experience and increased field reliability and robustness.

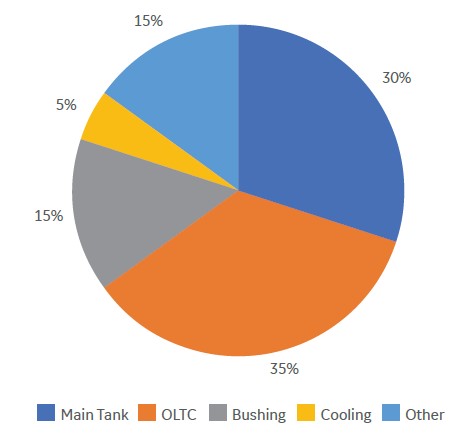

While on-line DGA is now widely accepted as the most effective method of assessing the condition of a transformer, it does not cover all the possible sources of issues. Subsystems like the tap changer, the cooling system or the bushings can generate their own problems if they are left unmonitored. The DGA 900 PLUS monitoring system integrates DGA measurement, additional sensors, analysis models and data handling features to address the majority of prevalent failure modes. This cost-effective package provides the condition assessment tools essential for the effective management and optimal utilization of this critical sub-station asset. It is most suited for monitoring large, mission critical transformers or compromised transformers with a view to extending their life and preventing any unexpected failure:

Key Benefits

- Modular and retrofittable architecture using selectable standard add-on cards

- Provides extensive remote insight into transformer condition and safe operation

- Enables correlation of data for validation and in-depth fault analysis

- Graphical presentation using built-in web-page based HMI and local color screen

- Full integration with GE’s acclaimed Perception™ Fleet asset management software

- From the only vendor with 15 years PAS experience and installed base of >15,000 units

Dissolved Gas Analysis (DGA) and moisture measurements of insulating fluids are recognized as the most important tests for condition assessment of transformers. In previous years, multi-gas DGA was traditionally confined to a laboratory environment, with infrequent yearly off-line manual sampling aiding time-based maintenance strategies.

However, as the global average age of transformers continued to rise, the possibility of rapid aging and even catastrophic failure between off-line tests also increased, leading many asset owners to adopt on-line DGA monitoring to provides remote alert and multi-gas diagnostic of deteriorating transformer condition.

This facilitated operational decisions without needing to go to site for manual oil sampling. It avoided unplanned outages, increased network reliability and enabled the move to condition-based maintenance.

In the early 2000’s, GE’s original Kelman™ range of on-line multi-gas DGA analyzers brought Photo-Acoustic Spectroscopy (PAS) measurement technology to the market. GE is now proud to introduce the Kelman DGA 900, its next-generation multi-gas on-line DGA and moisture analyzer. At its heart lies an evolved implementation of GE’s proven PAS technology, providing laboratory challenging levels of precision and repeatability with no consumables (carrier or calibration gases) and no need for frequent re-calibration. It also has enhanced computing power and scalable I/Os for future proofing and adding functionalities to grow each analyzer into a flexible transformer monitoring solution.

Transformer issues can now be detected in their infancy, making sure that they are fixed early so that the nominal expected life of the transformer can be achieved. Maintenance interventions can now be planned, reducing their length and their cost and causing less disruption to the network and customers. In addition, aging asset replacement strategies can be anchored on hard health condition data and not purely based on the age of the transformer.

Kelman DGA 900 PLUS further incorporates on-board calculations based on the very latest IEC®/ IEEE® thermal and moisture models standards and computed from the specific transformer characteristics obtained from the name-plate and test reports of the transformer.

The integrated Kelman DGA 900 PLUS comes with optional Input/Output (I/O) cards so that additional sensors can be attached to increase its measurement scope. With this add-on, the DGA 900 can continuously measures other critical parameters such as oil temperatures, load current, water content in oil, and cooling status which are complementary to the DGA information.

These models convert raw data into additional intelligent information to monitor the state of the transformer’s insulating system every 10 minutes and determine its long term aging profile. This information can also assist system operators in making critical operational decisions, particularly when it comes to safely overloading aging transformers by calculating the dynamic loading capacity. The aim of all the models is to aid in optimizing the transformer’s life (which is dictated by the state of its insulating system) and in deriving the optimum operating profile to maximize operational effectiveness.

A typical On-Line Tap Changer

A typical On-Line Tap Changer

On-Line Tap Changers (OLTCs) are complex mechanical devices with moving parts that wear over time due to the current they switch (contact wear) and the number of switches they perform (mechanical wear). An OLTC can operate many times a day, switching thousands of amps on each switch and sometimes over-using a limited set of contacts. This repeated use means that OLTCs require careful attention through inspection, replacement and refurbishment.

By monitoring the current position, the number of switching operations by position and the cumulated switched current load by position, an estimation of the contact wear can be obtained. In addition, the current consumption of the OLTC drive motor can be used to detect an increased difficulty in switching positions.

Finally, coking of the contacts will lead to increased arcing, to an elevated oil temperature in the OLTC compartment and thus can be detected by an oil temperature delta to the main tank. By monitoring these additional parameters, Condition Based Maintenance can be used on this key electro-mechanical component and an OLTC failure can be avoided, along with its usually not insignificant ensuing disruptions.

Simply fitted on the Bushing test tapping point

Simply fitted on the Bushing test tapping point

Bushing failures account for a large proportion of substation events that result in severe and costly damages and unfortunately even sometimes fatalities. Preventive maintenance, early bushing replacement and regular off-line testing have been employed to address this issue in the past. Monitoring transformer bushings is critical because bushings are constantly under high stress due to the line voltage and heat effect of the current flow. These stresses can be further aggravated by the presence of micro cracks from manufacturing, loss of mechanical strength due to aging, repeated thermal cycling (load + sun), pollution and external flashover eroding the porcelain, sludge and moisture in the insulating oil, and by the fact that new bushings have been made closer to design limits in order to reduce cost, size and weight.

The Kelman DGA 900 PLUS with bushing monitoring is an integrated on-line system that continuously monitors the condition of up to 6 bushings (3x HV and 3x LV). It uses custom bushing adapters (specifically designed for each bushing type).

It continuously measures the change in Capacitance C1 compared to the original nameplate value. It also measures the relative Power Factor (Tan Delta) change compared to the original nameplate value. If the reference voltage from a voltage transformer (phase to ground) information is available, then the real PF induced by the bushing can be calculated and displayed. This provides information similar to that obtained during off-line tests.

Partial Discharge Detection

PD is a localized breakdown of a small portion of a solid or fluid electrical insulation system that is under high voltage stress, which does not completely bridge the space between two conductors. PD on solid dielectrics results in localized gradual erosion of the insulation system that eventually leads to failure of critical insulation.

Using the same bushing adaptors, the DGA 900 PLUS offers the added advantage of measuring high frequency signals in order to monitor PD activity, giving an added level of protection for the main tank of the transformer. The amplitude of the PD pulses are recorded and used to calculate an overall measure of PD activity. Several methods are used to discriminate between internal PD and external noise (corona discharge). The BMT 330 also provides Partial Discharge Phase Resolve (PDPR) diagnostics.

Graphical Visualisation of the monitoring data generated using the backend analytical engine, provides clear diagnostic trends.